简介:BJ公司最近将他的TeleCoil 井下通信系统投入商业应用,旨在提升任何

连续油管作业的效率。该系统可以实时捕捉

井下作业数据,并已成功获取精确深度、温度以及压力信息,为北海地区的数个作业方提供技术信息服务。该系统可以在

连续油管作业期间,利用井下工具串采集和传输信息。采集信息可用于

射孔、设桥塞、确定流体位置等工序上。

Promising heightened efficiency of virtually any coiled tubing (CT) operation, BJ Services recently commercialized its TeleCoil downhole communication system. The system, which captures downhole operating data in real time, has already successfully gathered accurate depth, temperature, and pressure information for several operators in the North Sea.

The patent-pending system incorporates an instrumentation package in a customized bottomhole assembly (BHA) that captures and transmits information during the CT operation. This information is used to optimize the job, and verify depth measurements for activities including perforating, setting plugs, and certain fluid-placement applications.

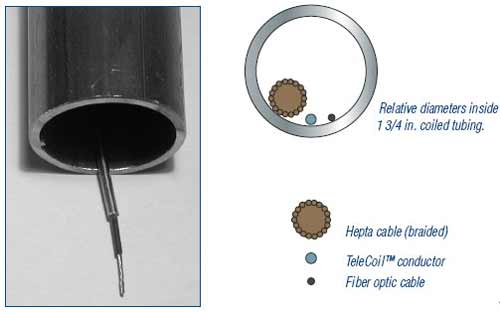

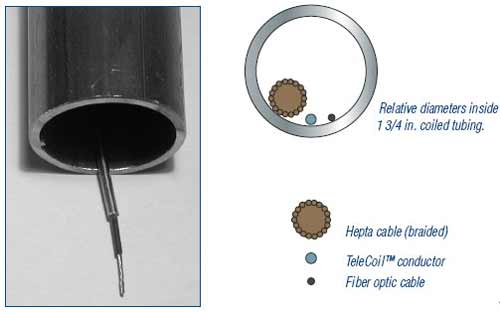

Close up of TeleCoil conductor in 1 3/4-in. coiled tubing and comparative size vs. hepta and fiber-optic cables.

Close up of TeleCoil conductor in 1 3/4-in. coiled tubing and comparative size vs. hepta and fiber-optic cables.

The TeleCoil system conductor is preinstalled inside the CT and is impervious to aggressive fluids such as acids, cement slurries, and sand-laden fluids used for abrasive perforating. A protective jacket provides superior strength to withstand dynamic tension and compression forces encountered during spooling and pumping operations. Additionally, the small-diameter conductor has negligible impact on pumping pressures or the overall weight of the reel.

At surface, the conductor connects to a data-acquisition system that processes and charts downhole measurements. The TeleCoil technology package attaches to the BHA with a standard-end connector and uses electric quick connectors, which require only a few minutes of setup time in the field. The system supports the use of commonly available logging suites and standard ball-activated tools.

BJ states that some of the applications that can benefit from TeleCoil include milling and cleanout operations; logging; mechanical intervention; and perforating, stimulation, and gas lifting.

One of the first applications of the TeleCoil system was a perforating operation on behalf of Talisman Energy (UK) in the North Sea, which was performed at depths up to 18,000 ft (5486 m). The operation presented some challenges related to temperature and mechanical issues, but BJ states that these were addressed by carrying out system refinements and upgrades to prevent them from reoccurring. As a result, the TeleCoil system provided real-time depth, pressure, and temperature data, making it possible for BJ to achieve accurate depth correlation throughout the operation.

"We are extremely pleased with the performance of our TeleCoil system in the harsh North Sea environment," said John Anderson, region vice president for Europe and West Africa, BJ Services. "The conditions, including bottomhole temperatures of more than 300°F [149°C], provided valuable experience."

In addition to the Talisman project, BJ Services recently used TeleCoil technology in a successful CT-conveyed perforating operation in Liverpool Bay, England. Variations and geographic expansion of the system are under way.

More information can be found at www.bjservices.com or by contacting Wendy Gray at

Wendy.Gray@bjservices.com.

杨宝剑 是全球

石油网的高级技术编辑,在

石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对“新技术新产品”的内容有任何问题或建议,请联系杨宝剑编辑Email:allenyo#zhenweiexpo.com (#变为@)欢迎您提供手中的最新技术文章!