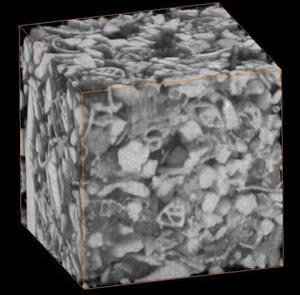

A sample of Ingrain’s “digital rocks” showing a 3.5 mm carbonate sample. Through its computational process, Ingrain provides fluid flow properties and elastic and electrical rock characteristics. (Image courtesy of Ingrain)

So many drilling, completion, and development decisions hinge on knowing a few simple rock properties: permeability, relative permeability, porosity, electrical conductivity, or elastic characteristics.

The problem is, these measurements aren’t actually “simple” when it comes to evaluating them in the ground. Many systems can provide some of the answers, of course ? wireline and while-drilling tools, core samples, even seismic data, in certain instances. But there’s always the element of uncertainty when it comes to scaling up a small measurement to represent the permeability or drive mechanism of an entire reservoir.

A new start-up in Houston is providing a service that might overcome these hurdles. Called Ingrain, it is the brainchild of Amos Nur and Henrique Tono, the latter of whom has degrees in geophysics from UC-Santa Barbara and Stanford University and a Ph.D. in rock physics from Duke University. On the surface his concept is simple ? provide physical properties of rocks to oil and gas companies. What makes it different from other measurements?

“We don’t measure the rocks physically,” Tono said. “We compute them. We put those rocks in a computer and we compute the properties.”

Fragments of reservoir rock are placed in a CT scanner, which takes a 3-D X-ray of the rock. Ingrain takes that image and puts it into a computer. “The experiments that would be run in the lab we run in the computer,” he said. Anyone who’s waited months for information to come back from a core lab can appreciate the simplicity of letting the computer do most of the work. Tono said his method can be done in a fraction of the time it would take in a lab. Also, he said, the measurements are more accurate, and the simulations can be done under circumstances that would be impossible to replicate in a lab setting. Finally, additional measurements can be taken.

“For example, we measure things in all directions, meaning we can get measurements of anisotropy in terms of permeability, relative permeability, electrical conductivity, elastic properties, etc.”

While Ingrain is just a year old, the concept behind it is not. “This is all based on patents that we have accumulated after 30 years of rock physics work at Stanford University,” Tono said. “It’s not something we kind of glued together.”

Tono has worked for years with Nur, who started the rock physics lab at Stanford more than 30 years ago. “We talked about taking this further, but both technology and the market weren’t quite ready for it,” he said. “About a year ago we looked at each other and said, ‘It’s time.’ And here we are.”

As with so many geophysical advances, one of the main enablers has been the vast increase in compute power. Tono said that even two years ago the service Ingrain provides would have been impossible. “The amount of computation that’s required to do a single calculation is immense,” he said. “The reason is that we’re computing everything in the actual complex rock. We’re not simplifying it or making models or taking short-cuts. There is real, rigorous mathematical computation going on.”

Secondly, the scanning technology is finally able to image at the resolution needed to correctly visualize the pore spaces.

Industry response has been “tremendous,” Tono said. Currently employing about 30 people, mostly in the Houston office, he has plans to open three additional offices, in Calgary, Saudi Arabia, and Rio de Janeiro, in the coming months.

“We went commercial just a few weeks ago,” Tono said. “Now we’re trying to keep up with the demand, ordering more equipment and hiring more people.”