Pressure test design and sampling prediction with the straddle packer module.

As wireline testing tool capabilities continue to evolve, the quality of formation sampling and testing services has decreased project cycle times and reduced development risks. The modular capabilities of Baker Atlas’ Reservoir Characterization Instrument (RCI) enhance the ability to record formation pressures and collect fluid samples in a wide array of geological environments and borehole conditions. Obtaining gas condensate samples in an oil-based mud (OBM) environment presents several challenges, including the low optical density of gas condensate and the possibility of the pumping pressure falling below the dewpoint pressure while pumping. High-quality pressure, volume, and temperature (PVT) data are critical because an inaccurate gas-to-oil ratio (GOR) estimate from a contaminated or misrepresentative fluid sample can lead to platform production problems and the inability to handle associated gas production. For production facilities to perform efficiently and be profitable, accurate determination of formation fluid composition is essential. The redesign of a production facility can disrupt fluid production and affect economic viability.

Pre-job modeling and execution

Pre-job modeling and planning and advanced downhole fluid analysis, along with post-processing and advanced deliverables services, were used on an exploratory formation tester run on a well in Alwyn North field in Block 3/9a of the Northern North Sea. An exploration well was drilled to the west of the main Triassic reservoir. The objectives for this formation testing run included:

• Determining horizontal and vertical continuity over the Triassic by acquiring formation pressures;

• Evaluating absolute pressures and possible pressure depletion due to the main Triassic production;

• Obtaining qualitative indicators

of permeability using the pressure tests; and

• Retrieving a downhole fluid sample from the Triassic reservoir.

The combination of services aided in the success of acquiring the first downhole fluid sample of a thinly laminated Triassic reservoir.

Near-wellbore numerical simulator

Extensive pre-job modeling was performed to determine the likelihood of obtaining representative samples at all intended depths and to choose the optimum tool configuration for sampling. Formation testing operations can require extended pumping, which can result in fishing for a stuck tool. Insufficient pump-out volume and deep invasion can result in the collection of a false representative sample. These situations tend to occur more often in deep, extended-reach wells offshore, where the cost of the rigs is significantly higher.

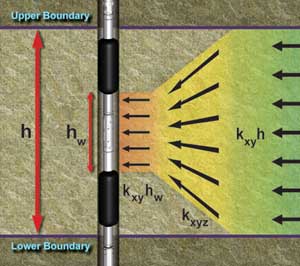

RCISim is a 3-D near-wellbore numerical simulator that models the sample clean-up process near the well bore as a function of several variables, including invasion diameter and viscosity of the invaded and native fluids for various sample zone thicknesses. The simulator is based on a black oil reservoir simulator capable of handling a 3-D multiphase flow in the near-wellbore area. Formation parameters of porosity, capillary pressure, relative permeability, permeability anisotropy, and formation thickness, as well as pumping rate, probe depth relative to the reservoir boundaries, and invasion depth were to be investigated.

Invasion was simulated by facilitating a mud filtrate injection at a low rate for a period of time calculated to provide the input depths of invasion, 7 in. and 15 in. A wait time between injection and sampling can be specified to simulate the time between the end of invasion and the beginning of sampling. Contributing gravity and time affects results in an invasion profile deeper toward the base of the reservoir model compared to the top of the structure. The clean-up volume predicted by the RCISim software is the required fluid production from the formation to achieve the target level of contamination at the sand face. An additional clean-up volume must be pumped to consider the tool’s flow line volume.

In-depth sensitivity analysis

When sampling in a thinly laminated Triassic reservoir, the simulator was needed to assist in selecting the sampling depth, the pumping rate, and the minimum required time and volume necessary to reach the targeted contamination level. The results of the sensitivity analysis also facilitate optimum tool configuration to ensure a successfully executed wellsite operation.

After the fluid has been characterized and the reservoir’s fluid parameters have been established for pre-job modeling and planning, the parameters are used in the sensitivity analysis. The sensitivity analysis involves a pre-job modeling matrix using a series of calculations that provide different outputs based on a range of input parameters. Sensitivity analysis results are analyzed to estimate total drawdown, pumping time, and total clean-up volume. These results are also used to investigate the effects of formation permeability anisotropy, invasion depth, and bed thickness. After the variations have been examined, conveyance methods and risk-reduction technologies confirm the optimal tool configuration and determine the risks associated with the job.

Modeling versus execution results

By comparing two sampling scenarios based on the formation tester module, pre-job modeling helped determine which hardware would be more efficient in this particular environment: a single-probe module or a straddle packer module. The comparison uncovered advantages and disadvantages with using either formation tester module under various conditions.

Initially, the straddle packer module was thought to provide the best chance of acquiring a sample. The pre-job modeling results, concluded that the single-probe module would be more suitable in this formation as there were shallow invasion depths and high permeability. The simulation results indicated that high-quality samples were achievable at all intended sampling depths within a reasonable amount of time.

Subsequent PVT lab testing revealed the contamination of the recovered condensate sample was between 2% and 6%. Modeling and planning provided the data needed to determine a suitable formation tester type and the estimate of uninterrupted pumping time to be expected. The comparison between the RCISim clean-up prediction results and the clean-up prediction from the real-time near-infrared spectrometer sensor (including the post-acquisition laboratory analysis results) indicated the results were in agreement.

Pre-job planning is critical to the success of retrieving a representative, uncontaminated downhole fluid sample regardless of whether it is a water or hydrocarbon sample, especially when using OBM or synthetic mud.

The results from pre-job modeling and planning, advanced downhole fluid analysis, and post-processing and advanced deliverables services helped secure decisions on whether or not to sample at certain depths. Simulation results indicated that obtaining high-quality samples within a reasonable amount of time was possible at all intended depths, and this contributed to the success of the sampling job. The combination of services used for this sampling job provided the tools and data necessary for obtaining the first downhole fluid sample from this Triassic Reservoir.