简介:WellWatcher Flux是斯伦贝谢完井技术之一,组件包括测量仪、DTS系统、智能接箍等。能够在不停产的情况下测量深水油藏性能。

Since debuting in 2008, Schlumberger’s WellWatcher Flux sensor array system has garnered industry recognition and field success. At a recent Schlumberger-sponsored technology day in Houston, the oilfield services provider highlighted the system’s ability to measure reservoir properties from deepwater wells without choking back production.

“Prior to the WellWatcher Flux, reservoir measurements like this were not possible in subsea producing wells because of problems involved in deploying the sensors,” said John Lovell, Schlumberger’s system manager, Distributed Temperature Sensing (DTS). “This nonintrusive fullbore system records reservoir data on the sandface of subsea wells, with no intervention required for logging.”

Lovell explained that the system incorporates electromagnetic induction for wireless communication and power transmissions between the upper and lower completions. “This electrical, rather than fiber-optic, system’s inductive coupling feature allows for wireless power and telemetry. There is no need for rotation of the couplings to align cables.”

The couplings are fully integrated into the completion hardware, allowing high-resolution digital sensors to be used on the sandface. The system is reportedly robust enough to operate in the presence of downhole debris, vibration, and potential wellbore misalignment. Combined with thermal modeling software, the system allows flow events to be interpreted even in high-angle wellbores.

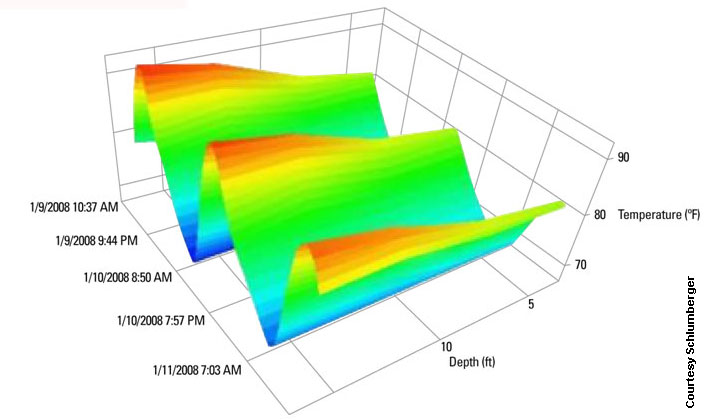

Temperature data recorded from the WellWatcher Flux array while it was spooled on a reel at the operating base.

Lovell explained that operators can use the WellWatcher Flux with modeling software to analyze reservoir data in the office rather than at the field site. This allows them to more efficiently identify prolific producing zones, characterize flow profiles along the sandface, monitor reservoir changes and make appropriate adjustments quickly, and optimize overall production.

Lovell said that six systems have been deployed in Southeast Asia following a comprehensive two-year engineering development program. The first deployment, for a subsea field in the Bay of Bengal, will be used to monitor temperatures to establish flow allocation profiles across each wellbore, determine reservoir depletion and channel connectivity, and plan subsequent infill drilling to optimize reservoir drainage.

WellWatcher Flux was one of several technologies highlighted by Schlumberger’s Completions group during the technology day. The entire WellWatcher Permanent Monitoring system was on display, including:

For more information, visit Schlumberger’s WellWatcher website.

杨宝剑 是振威(全球)石油网的高级技术编辑,在石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对该项新技术有任何的疑问,或者对“新技术新产品”未来的内容有任何问题或建议,请联系杨宝剑编辑 +86 10-58236512 Email:allenyo@zhenweiexpo.com 欢迎与行业互动!