简介:卡梅隆DC采油树全电化控制系统,为四井应用,其中一个树可以调节为失效备用树。节流管汇安装于水深131英尺处,由11.2英里远的平台来控制。系统的顶部关键部件包括一个主控站,监控海洋系统,四个电源与通信单元,每个采油树两个。

Cameron’s DC Tree made a splash at the recent Offshore Technology Conference after enjoying its first installation for Total E&P Nederland B.V. in the Dutch Sector of the North Sea in September 2008. The system includes a three-well template/manifold with a two-well initial installation and the option for a third. The all-electric control system is configured for a four-well application, designed to accommodate the fourth tree as a step-out. The template/manifold is installed in 131 ft (40 m) of water and is controlled by an existing platform 11.2 miles (18 km) away. Production is piped 6.2 miles (10 km) to an unmanned platform.

Key topsides components for the system include a master control station, which controls and monitors the subsea system, and four electrical power and communication units, two for each tree.

Without the burden, limitations, and expense of hydraulics, the system delivers key advantages over conventional systems, including savings in cheaper umbilicals, host facility space and weight savings, and the elimination of hydraulic fluid costs. Additionally, step-out distance is virtually unlimited, and the system can operate in as much as 15,000 ft (4,572 m) of water.

Because it is all-electric, it provides full compliance with zero tolerance of fluid emissions, and the size of the umbilical is greatly reduced.

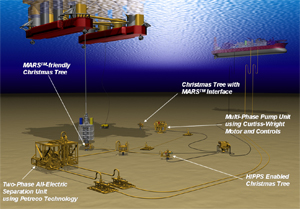

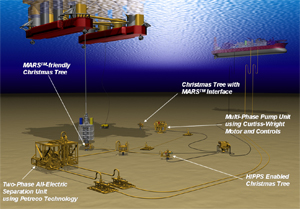

Cameron is using the DC Tree in conjunction with other subsea technology, primarily its high-integrity pressure protection system (HIPPS) and its multiple application re-injection system (MARS), to act as “enablers” to its subsea processing portfolio. HIPPS protects flowlines against overpressure. Equipped with intelligent safety and control systems, the system meets stringent safety levels and ensures constantly high production levels. Additionaly, HIPPS offers the flexibility to extend field layouts and to branch off new lines from existing systems, even when the pressure ratings are different.

MARS enables any process to be fitted to any well at any time. This is achieved by establishing a retrofit coaxial access port which has been compared to a USB port for a wellhead. Unplanned maintenance no longer requires major field shutdowns or infrastructure decommissioning This technology delivers a low-cost and flexible field development strategy for new and existing fields.

For more information, visit

www.c-a-m.com .

杨宝剑 是振威(全球)石油网的高级技术编辑,在石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对该项新技术有任何的疑问,或者对“新技术新产品”未来的内容有任何问题或建议,请联系杨宝剑编辑 +86 10-58236512 Email:

allenyo@zhenweiexpo.com 欢迎与行业互动!