简介:AeroGo 公司开发出一款气垫运输装置,用于转移大重量的钻机设备,引起了油气行业的关注。该汽轮能够使重物完全浮在一个与地面几乎没有摩擦的气垫之上,能够干净利落而又平稳的转移重物。搬运中还可以各个方位的转向移动,对地面没有特殊要求,尤其适合寒冷北极地区地面有冻土保护要求的钻井作业区。

A novel transportation technology that allows heavy machinery to float on a cushion of air is gaining the attention of the oil and gas industry. Heavy-load transport specialist AeroGo is using its air-caster technology to move a mobile drilling unit for a southern California operator, minimizing wear on the surface of roads.

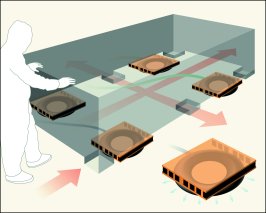

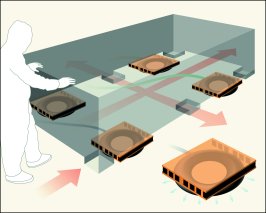

The AeroGo’s air casters have been used for many industrial applications that require safe and efficient transport of heavy loads. The principle of operation calls for an air caster to be positioned beneath a heavy load, and an air film is created by pumping compressed air into the circular caster’s diaphragm and center plenum chamber. The air pressure in the caster builds, eventually reaching a point where it exceeds the weight of the load; at that point, air slowly and evenly escapes between the caster’s diaphragm and the surface, creating a nearly frictionless film of air that is only 0.003 to 0.005 in. thick. The load can then be virtually floated omnidirectionally, with little or no damage to surface.

For the drilling-rig application, AeroGo is supplying four custom-designed traction drive assemblies to transport a 625-ton mobile drilling rig from well to well for Warren Energy and Production’s oil production complex in Wilmington, California. The four air-caster drive assemblies are pinned to underneath the rig’s skid structure via special frameworks, which hold the casters and ensure that they maintain contact with the concrete median beneath the rig.

Each caster provides 10,000 lbf of pressure, resulting in a total of 40,000 lbf of pressure to lift and move the rig. A sophisticated computer control system coordinates the four drives, enabling them to act as a single unit with simple commands. The system also allows for precision steering and placement of the rig, which can move in any direction and rotate around its center. The rig can move from wellhead to wellhead at a speed of 2 mph.

The operator moves the rig on an average of once every ten days and in an irregular pattern that is dictated by drilling requirements. The AeroGo system makes these moves more efficient, as equipment such as drill pipe can be stored and moved on the rig rather than having to be removed and replaced once the move is complete. In addition, the system allows for simple control of rig movement in any direction that operators dictate via a radio-remote pendant, much like that used in a remote-controlled car or industrial crane.

AeroGo sees their air-caster technology as an improvement for any land-based rig transport, particularly for operations in Arctic regions, which have to take special precautions to minimize damage to the tundra during transportation.

杨宝剑 是振威(全球)石油网的高级技术编辑,在石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对该项新技术有任何的疑问,或者对“新技术新产品”未来的内容有任何问题或建议,请联系杨宝剑编辑 +86 10-58236512 Email:allenyo@zhenweiexpo.com 欢迎与行业互动!