简介:美国赖斯大学和M-I SWACO钻井液公司协议合作,将纳米新成果转化到石油工程方面来,提升采收率。即开发纳米级的石墨添加剂,改良钻井液,解决毛细孔的堵塞问题。

Houston’s Rice University and M-I SWACO, the world’s largest producer of drilling fluids for the oil and gas industry, have signed a research agreement to use nanotechnology advances to improve the productivity of wells. The project aims to develop a nanoscale graphene additive for drilling muds that will prevent the common problem of pore clogging.

M-I SWACO will spend USD 450,000 over two years for research conducted in the laboratories of James Tour, Rice’s Chao professor of Chemistry and professor of mechanical engineering, materials science, and computer science.

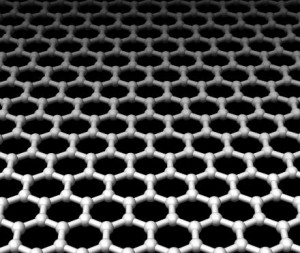

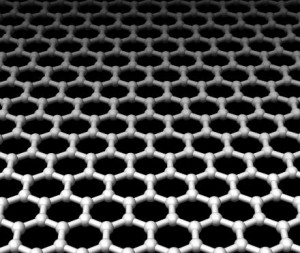

“Graphene is a single sheet of graphite, 1 carbon atom thick. It is the thinnest material you can develop, essentially a 2D structure,” explained Tour. “We have been able to make sheets of graphene that are 25 μm in diameter yet only 1 nm thick. Our laboratory studies have shown that at very low dosages, graphene has an incredible ability to plug filters.”

It is this plugging efficiency that M-I SWACO wants to exploit for drilling-mud applications. Conventional water- or oil-based muds are forced downhole through a drill to keep the drillhead clean and to remove cuttings as the fluid streams back up toward the surface. But the fluids themselves?which contain many additives? can clog pores in the shaft through which oil should flow.

Tour says that a combination of oil-soluble graphene and water-soluble graphene oxide, at dosages that are a fraction of the nanoclay particles used for plugging prevention, can be added to the drilling mud. The particles would be forced by the fluid’s own pressure to quickly form a thin filter cake on the shaft wall, before the muds can clog the pores.

When the drilling fluids are removed along with the drillhead, the reservoir’s formation pressure would force the graphene filter cake out through the pores and into the shaft, allowing hydrocarbon production to occur without obstruction. “When you release the hydrostatic pressure and pull the drill bit out, there’s much more pressure inside the rock than in the hole,” Tour said. “The filter blows out and the oil flows.”

James Bruton, M-I SWACO’s vice president for research and engineering, said the time is right for his company to investigate the use of nanoparticles, particularly when one considers the high cost of drilling fluids. He said the cost of drilling fluids can reach USD 200?300/bbl, and a well being drilled in the Gulf of Mexico might require more than 20,000 barrels of mud. “It’s not a cheap undertaking for our customers, so the performance of the fluids is paramount,” he said.

Graphene is an atomic-scale honeycomb lattice made of carbon atoms.

Tour’s research group has been conducting basic research on graphene and graphene oxides since they were first isolated in 2004. He emphasized that these nanomaterials are “clean tech” components in an environmentally sensitive field. “We’ve shown them to be nontoxic in many forms,” he said. “It’s all graphite-based, and that often comes from the ground anyway.”

The scope of research between Tour’s group and M-I SWACO will involve taking the fundamental understanding of how graphene behaves in water to plug filters and expanding this to develop appropriate drilling mud formulations that include graphene. “While we understand graphene’s behavior in water, we now need to understand how graphene’s plugging ability might be affected by the presence of any of the components in a drilling mud,” Tour said.

While the company’s current focus is on drilling muds, Bruton said future research would focus on using graphene in completion fluids and other drilling products. “People often ask me what are we developing, and most of the time they want to know what’s coming out tomorrow, next week, next month, or next quarter,” Bruton said. “In reality, I have to worry about things we’re going to implement two to five years from now. That’s where the step changes are. That’s where we hope and believe nanotechnology, with Rice and Jim’s group, will help us get to where we need to go.”

To learn more about the nanotechnology research being undertaken at Rice University, visit the James M. Tour Group website.

杨宝剑 是全球石油网的高级技术编辑,在石油技术资讯行业有八年的学识和经验。他源源不断地提供石油行业全球最新的技术创新、研发成果、现场应用情况等信息。如果你对“新技术新产品”的内容有任何问题或建议,请联系杨宝剑编辑 +86 10-58236512 Email:allenyo@zhenweiexpo.com 欢迎您提供手中的最新技术文章!