水是宝贵的自然资源,是地球上一切生物赖以生存的物质之一。目前全世界的淡水资源仅占总水量的2.5%,其中70%以上被冻结在南极和北极的冰盖中,加上难以利用的高山冰川和永冻积雪,有86%的淡水资源难以利用。

气候变化和全球工农业的迅速发展使得淡水资源缺乏的问题日益严重,甚至于部分沿海城市也严重缺水。因此,海水淡化和废水利用技术逐渐兴起,在人类的生产生活中发挥了越来越重要的作用。其中,一家中国水处理企业通过自己的努力走到了行业的前面,多年来研发生产了大量水处理设备,远销世界各地,得到了各国客户的广泛赞誉。

2017年3月20日-22日,这家新型高科技企业——烟台洁通水处理技术有限公司将在北京·中国国际展览中心(新馆)举行的cippe2017第十七届中国国际石油石化技术装备展览会亮相,向专业观众展示其先进的水处理技术。

烟台洁通水处理技术有限公司是专业从事工业水处理、海水淡化、电解制氯、废水处理等,集水处理技术咨询、水处理产品设计、开发、生产、销售于一体的新型高科技企业,公司取得了二十多项发明专利及实用新型专利,已通过ISO9001:2008质量管理体系标准、ISO14001:2004环境管理体系标准和OHSAS18001:2007职业健康安全管理系统标准认证。

烟台洁通秉承“以技术为先导,以质量求生存,以信誉求发展”的宗旨,先后开发了十一大系列90多种水处理产品,其中部分水处理产品被中石油、中石化、中工国际选为指定产品。先后为古巴、阿曼电站海水利用提供大型电解海水制氯装置,为阿曼生产的海水淡化设备直接将海水处理至高纯水,以很高的性价比得到了用户的赞誉。工程遍布世界各地,产品出口韩国、伊拉克、沙特、哈萨克斯坦、尼日利亚、乍得、苏里南、乌克兰、厄立特里亚等多个国家。

产品介绍

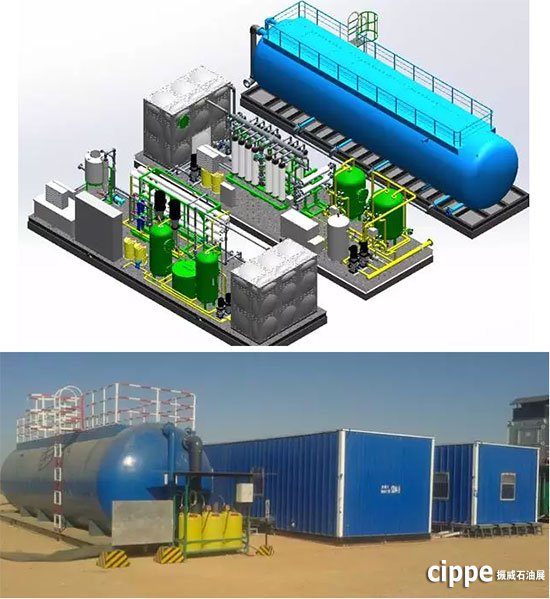

1.海水淡化注采水处理系统

Seawater desalination injection and production water treatment system

膜法海水淡化设备是在压力驱动下海水通过半透性螺旋卷式膜进入膜的低压侧,水中多余盐分和矿物质被阻挡在高压侧并随浓缩海水排除,从而得到淡水的工艺。

The water crisis has an unprecedented demand for sea water desalination. Membrane seawater desalination plant get the fresh water by using pressure drive the seawater through the semi-permeable spiral wound type membrane into the low-pressure side, the excess salt and minerals in the water is blocked in the high-pressure side and discharged with the concentrated seawater.

中石油阿曼石油开采-集装箱式海水淡化设备720t/d

CNPC Oman oil extraction – container seawater desalination plant 720t/d

2.高干度注汽锅炉高纯水处理系统

High dryness steam injection boiler high pure water treatment system

注汽采油技术是稠油开采的最主要方法,为了适应油田稠油开采的工艺要求,采用直流式高压蒸汽锅炉(也称为注汽锅炉)作为蒸汽的发生器,目前采用软化水生产80%干度的蒸汽(湿蒸汽), 为防止炉管内壁析盐,确保安全生产,由20%的饱和水携带盐份。由于稠油的采收率与蒸汽的干度密切相关,我公司生产的高纯水处理系统通过降低锅炉给水装置含盐量,在保证锅炉安全生产的前提下,将蒸汽干度提供到95%,并满足水的最大利用率,该系统在我国稠油生产的主产区胜利油田、辽河油田得到广泛应用。

Steam injection technology is the most important method of heavy oil exploitation, in order to adapt to the heavy oil mining process requirements, high pressure steam boiler (also known as steam injection boiler) is using as the steam generator. Currently using softened water to produce 80% dry steam (wet steam) to prevent salt on the inner wall of furnace tube and ensure the safety of production. Since the recovery of heavy oil is closely related to the dryness of the steam, the high pure water treatment system manufactured by our company can provide the steam dryness to 95% by reducing the salt in boiler feeding water to maximum utilizing of water and ensure the safe production of the boiler. This system has been widely used in main heavy oil production areas of Shengli Oilfield, and Liaohe Oilfield.

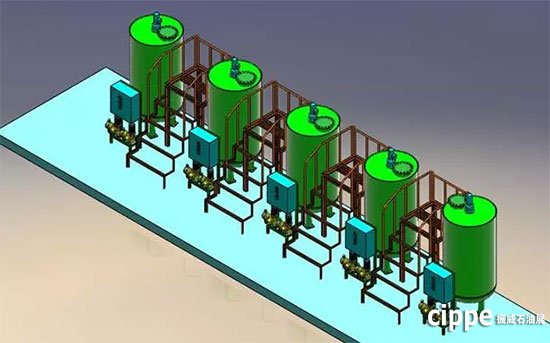

胜利油田-撬装式高纯水处理设备1000t/d

Shengli Oilfield – skid mounted high-pure water treatment plant 1000t/d

3.油田含油污水资源化利用项目

Oil-bearing waste water utilization projects

目前,全国部分油田的主力油区已进入开发后期,随着部分区块注汽、注清水等因素的影响,采出水量逐年上升,富余污水逐年增多。国内油田污水存在注采不平衡问题越来越严重,富余污水具有高的矿化度、高硬度、高温的特点,我公司提供的含油污水资源化利用解决方案,可以实现产品水直接进入注汽锅炉。

At present, part of the main oil field has entered into the later development period, with the affection of steam injection and water injection, the produced water and surplus sewage increased year by year. The problem of imbalance of injection production is more and more serious in domestic oilfield, the surplus sewage has the characteristics of high salinity, high hardness and high temperature, our company is capable of providing oil-bearing waste water resource utilization solutions, which can achieve produced water directly into the steam injection boiler.

胜利油田-含油污水处理系统1000t/d

Shengli Oilfield -Oily wastewater treatment system 1000t/d

4.超临界注汽锅炉水处理系统

Supercritical steam injection boiler water treatment system

随着我国稠油开采的不断深入,超深稠油的开采只能通过26MPa超临界压力注汽锅炉来实现这部分储量的开发利用。

With the deepening mining of heavy oil in China, ultra-deep heavy oil mining can only be achieved by using 26MPa supercritical pressure steam injection boiler.

胜利油田河口采油厂-车载式水处理系统11.5t/h

ShengliOilfield Hekou Oil Production Plant – Trailor type Water Treatment System 11.5t/h

5.炼油厂高硫化物污水处理项目

Oil Refinery Plant high sulfide wastewater treatment project

炼油厂含碱废水是10%氢氧化钠溶液用于脱除高含硫原油中硫组份而形成的含油污水,污水的主要污染物包括悬浮物、硫化物(有机硫、溶解硫化氢)、碱及溶解性盐等多种复杂成分,污水的PH≥12。

Oil Refinery plant alkali wastewater is produced during the removal of sulfur component in high sulfur oil with 10% sodium hydroxide solution, the main pollutants of sewage including suspended solids, sulfide (organic sulfur, dissolved hydrogen sulfide), alkali and soluble salts and other complex components, sewage PH ≥ 12.

6.海上钻井平台电解海水防污系统

Offshore drilling platform seawater electrolysis anti-fouling system

海水电解制氯系统采用先进的电解技术,通过电解海水可以现场生产浓度200-1000ppm的次氯酸钠溶液,次氯酸钠溶液通过计量泵投加到海水中,能够有效控制海水微生物、贝壳类海生物等生长,在滨海工业中得到广泛应用,设备可满足每小时100万吨以下海水杀菌处理。

The seawater electrolys is chlorine system adopts the advanced electrolysis technology and is capable of producing sodium hypochlorite solution with the concentration of 200-1000ppm by electrolyzing seawater. The sodium hypochlorite solution is dosed directly to the seawater through the metering pump, which can effectively control the growth of seawater microbe and shellfish. Seawater electrolysis chlorine system is widely used in coastal industry, which can accomplish 1 million tons below per hour of sea water sterilization.

古巴哈瓦那电厂 - 电解海水产生次氯酸钠装置72kg/h(有效氯)

Havana power plant inCuba - seawater electrolysis online sodium hypochlorite plant 72kg/h (activechlorine)

荣誉资质